October 3rd, 2019

Flexible electronics have the potential to help monitor, and even modulate, a number of physiological parameters. While stick-on heart monitors can be manufactured as one-size-fits-all, in applications such as electronic bandages that can monitor and treat a wound, it’s best to be able to create custom devices that suit each patient’s needs.

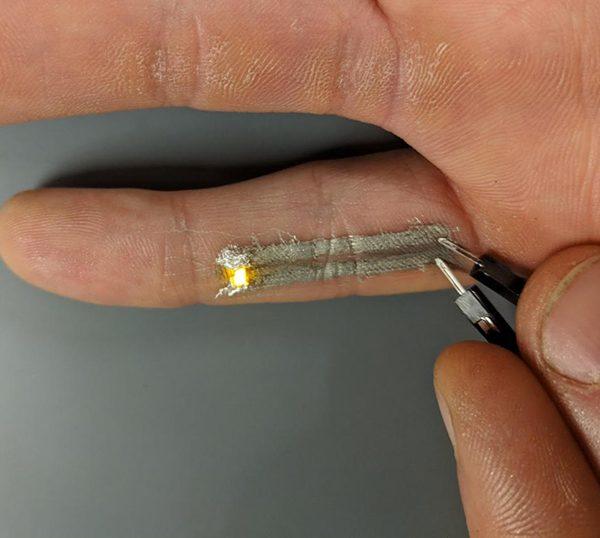

Currently, making flexible electronics requires harsh processing, including chemical baths, hardening processes, and high temperature baking to purify the materials being used. Now, researchers at Duke University have come up with a way to directly print functional flexible electronics directly onto the skin, paper, bandages, and other flexible and moving devices. The capability may allow clinicians to print diagnostic and therapeutic devices right onto patients or onto bespoke medical tools.

To read the complete article, click here.